Why is the current CNC precision part processing increasingly important? What types of CNC precision part processing is divided into? How to distinguish it?

1. Compound processing machine tools linked to high -speed, fine CNC lathes, cargun centers and four -axis. Firstly, meet the needs of aerospace, aviation, instruments, instruments, instruments, electronic information and biological engineering.

2. High -speed, high -precision CNC milling machine and high -speed and high -precision vertical processing centers. Firstly to meet the processing requirements of large -scale messy structural brackets, shells, boxes, light metal material parts and fine parts of the car engine cylinder compact and aerospace, aerospace air, and high -tech.

3. Heavy and overweight CNC machine tools: CNC floor -to -floor milling beds, heavy CNC Dragon Gate Milling Mills and Longmen Machining Center, Heavy CNC Hilemi Line and vertical Motors, CNC Heavy Tocate Machines, etc. , Ship and ship hosting, heavy mechanical manufacturing, large mold processing, steam turbine cylinder and other professional parts processing needs.

4. CNC grinding machine: CNC ultra -fine grinding beds, high -speed high -precision crankshaft grinding beds and camshaft grinders, various high -precision high -speed special grinding machines, etc. to meet the fine super fine processing needs.

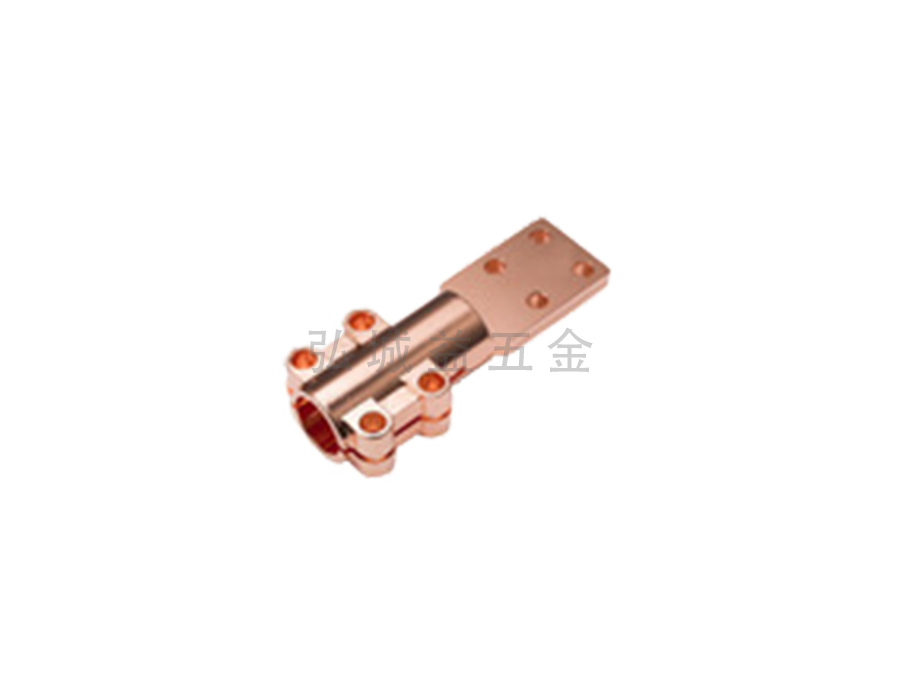

5. CNC electricity processing machine tools: Large fine CNC electro -spark -shaped machine tools, CNC low -speed wire wire electro -spark cutting machine tools, fine small pore electric machining machine tools, etc., first meet large and fine mold processing, fine part processing, conehole or alien holes Special needs of processing and aerospace, aerospace and other occupations.

6. CNC metal molding machine tools (forging equipment): CNC high -speed fine plate stamping equipment, laser cutting composite machine, CNC powerful rotary compressor, etc., first meet the high -efficiency production needs of professional board gold such as cars, motorcycles, electronic information industries, home appliances, etc. And the processing needs of various thin -walled, high -strength, and high -precision transformation parts in the hub and military industry.

7. CNC special machine tools and production lines: Flexible processing automatic production line (FMS/FMC) and various special CNC machine tools. This type of production line is for professional processing cylinders, cylinders, gearbox boxes, etc. and multi -variety changes for cars, home appliances and other varieties. Processing needs of batch shells and box parts.