1. Summarize parts with messy shapes. Any planar curve can be approached with a straight line or an arc, and CNC CNC lathe machining has the function of arc interpolation, which can process various miscellaneous parts. 2. Lathe parts with high precision requirements. Compared to CNC CNC lathes, they have good rigidity, high manufacturing accuracy, accurate tool setting, and convenient scale compensation, so they can process parts with high scale accuracy requirements. 3. Most suitable for multiple varieties of small and medium-sized batch parts. With the gradual decrease in the production cost of CNC CNC lathes, the situation of processing large quantities of parts has also emerged, both domestically and internationally. When processing small batches and single piece production, it is also possible to shorten the debugging time of the program and the preparation time of the tooling.

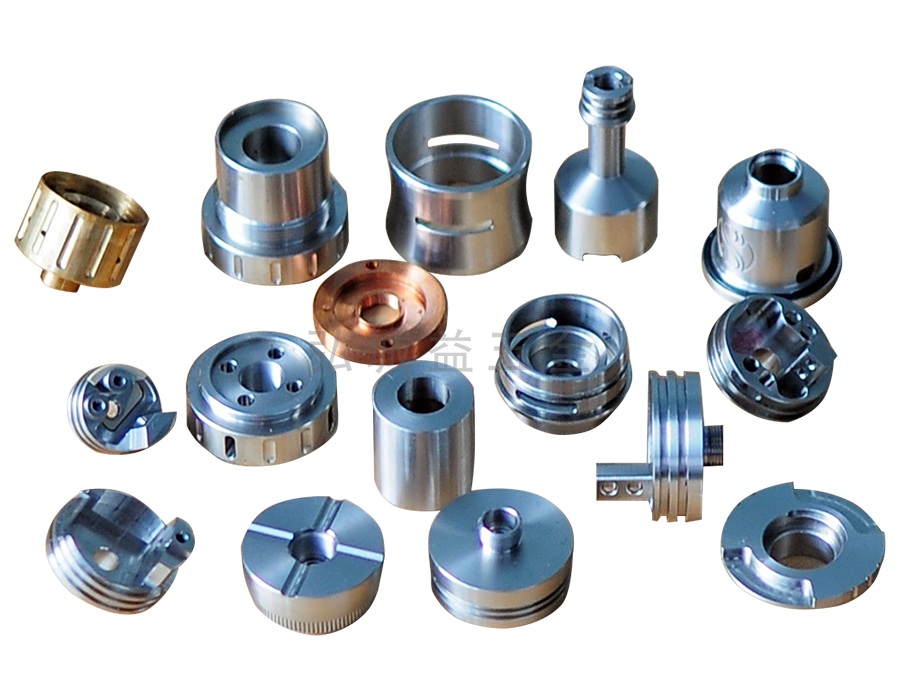

Only by scientifically handling CNC lathe processing, fully understanding the characteristics of CNC lathe processing, and coordinating the balance of various production links, can its economic benefits be truly realized. Parts suitable for CNC lathe machining:

1. Summarize parts with messy shapes. Any planar curve can be approached with a straight line or an arc, and CNC CNC lathe machining has the function of arc interpolation, which can process various miscellaneous parts.

2. Lathe parts with high precision requirements. Compared to CNC CNC lathes, they have good rigidity, high manufacturing accuracy, accurate tool setting, and convenient scale compensation, so they can process parts with high scale accuracy requirements.

3. Most suitable for multiple varieties of small and medium-sized batch parts. With the gradual decrease in the production cost of CNC CNC lathes, the situation of processing large quantities of parts has also emerged, both domestically and internationally. When processing small batches and single piece production, it is also possible to shorten the debugging time of the program and the preparation time of the tooling.

4. Parts with low surface roughness values. Generally, a lathe has a stable rotational speed, and the cutting speed varies with different diameters. For example, CNC CNC lathes have the function of constant linear speed cutting. When turning the end face and outer circles with different diameters, the same linear speed can be used to ensure that the surface roughness value is small and consistent. When processing surfaces with different surface roughness, lower feed rates are used for surfaces with lower roughness, while higher feed rates are used for surfaces with higher roughness, which has good variability and is difficult to achieve on general lathes