1. Industry Development Overview

The manufacturing industry is the core industry of the modern industrial system, and its technological level reflects the level of technology, international competitiveness, and comprehensive national strength; Manufacturing products can be widely used in military and civilian fields such as national defense, healthcare, aerospace, transportation, electronics, etc. It is an industry widely supported and developed by major industrial powers in the world.

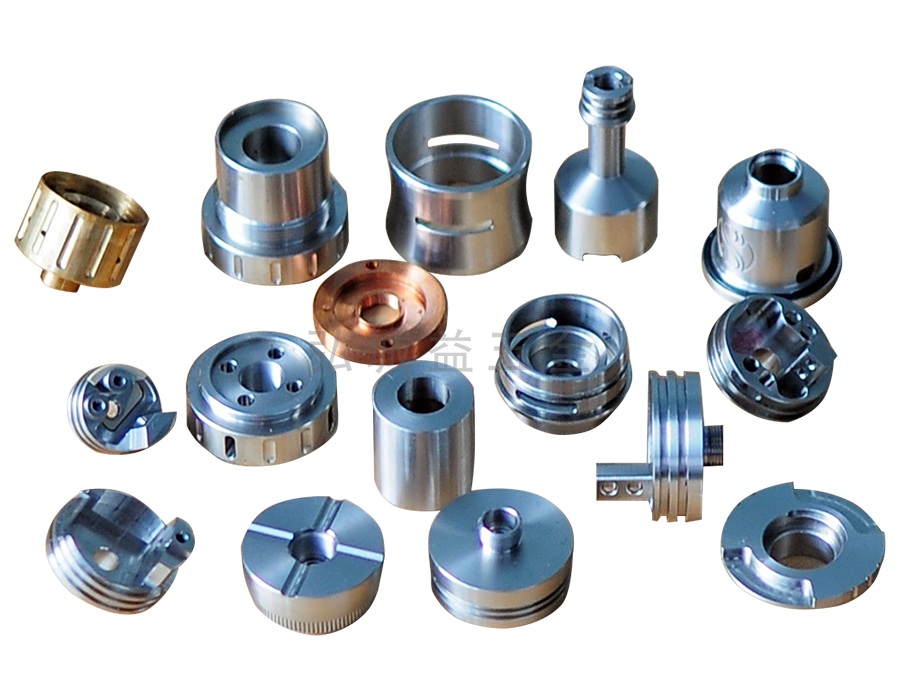

However, China's manufacturing industry is facing a significant gap between being "large but not strong" and the world's manufacturing powerhouse, with one prominent manifestation being the lagging processing capacity of supporting components. Precision components are usually the core components of a complete machine product, ensuring the functionality of the product. Therefore, the quality, consistency, durability, and other requirements of precision components are very high.

There are a large number of precision CNC machining manufacturers in China, with uneven technological levels and processing capabilities. Although some domestic supporting processing manufacturers can meet the processing quality requirements of precision parts by purchasing advanced production equipment, it is often difficult to produce in bulk and maintain the stability and consistency of product quality under controllable costs.

To achieve high-quality processing and manufacturing under batch production conditions, not only advanced production equipment and other hardware equipment are required, but also scientific and reasonable production processes need to be designed and implemented based on the product characteristics and customer needs of the components, balancing the processing quality and the constraints of product interaction, such as product delivery and cost control, to achieve the combination of equipment, optimized tools, personnel and other production resources; At the same time, in order to ensure the effective implementation of the production process, processing manufacturers also need to establish a comprehensive quality control system and equip a disciplined production team.

2. Industry Development Trends

(1) The application industry of CNC machining is more extensive. At present, domestic manufacturing and processing manufacturers mainly focus on electronic products, home appliances, automobiles, and other industries that support the processing of components. In the future, with the upgrading of China's manufacturing industry and the deeper integration of China's manufacturing industry with the global manufacturing industry chain, domestic precision machining can be applied to a wider range of fields both domestically and internationally, such as aerospace, intelligent equipment, rail transit, new energy, etc.

(2) The automation level of manufacturing and processing equipment is constantly improving. The automation application of equipment can reduce labor costs, improve product accuracy and stability, and improve production efficiency. With the continuous increase in labor costs, manufacturers and processing manufacturers are increasingly willing to use automated equipment.

(3) The concentration of the industry is constantly increasing. At present, domestic precision manufacturing and processing factories are relatively scattered, and the technical level is uneven. With the overall upgrading of China's manufacturing industry, manufacturers and processing plants with small scale, outdated equipment, and slow technological improvement will gradually be phased out. Manufacturers with certain scale and strength can gradually expand their market share, enhance their influence in the industry, and establish their own brands.