There are various types of thin-walled parts and they are widely used. With the development of the aerospace industry, materials and components used in aerospace equipment have the characteristics of being light and very thin. So thin-walled parts are widely used in the aviation industry. The processing of thin-walled parts is relatively difficult, and traditional machine tools lack processing accuracy, cutting force, temperature difference, and impact force. To meet the requirements of high-precision and efficient production, precision mechanical processing can greatly expand the scope of thin-walled parts processing.

Thin walled parts have low rigidity, large metal removal amount, and difficult to control machining accuracy. Therefore, the primary problem that CNC machining needs to solve is to control and reduce deformation. The reason for this is that during the cutting process, the thin-walled wall undergoes deformation under the action of cutting force, which leads to a "waist shaped" phenomenon with an ellipse or a small center and a large two ends. Other thin-walled casings are prone to thermal deformation due to poor heat dissipation during processing, making it difficult to ensure the processing quality of the parts.

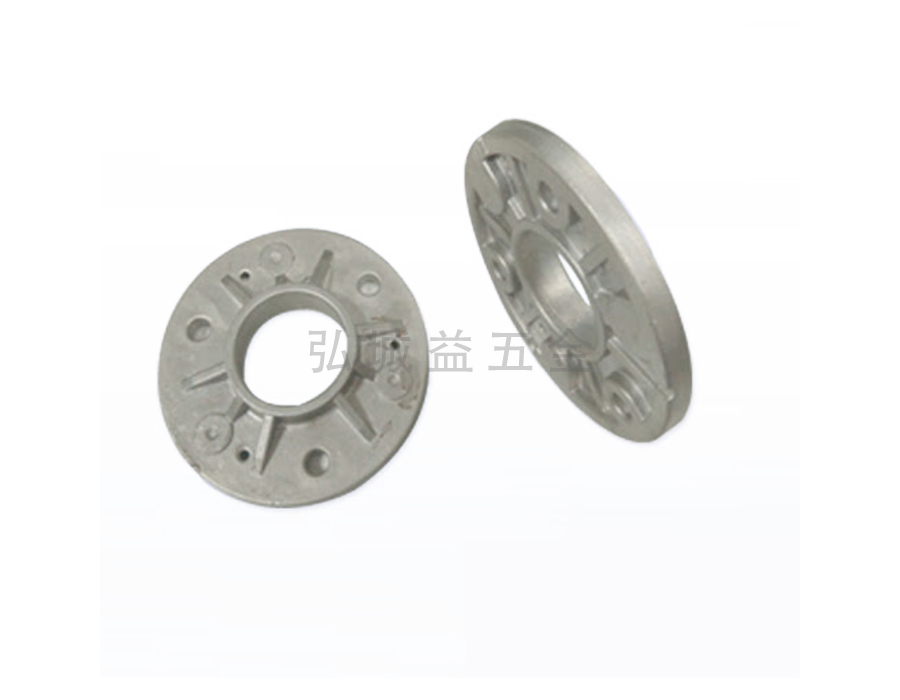

A clever method for processing thin-walled parts, using vmc850 to process thin-walled pipe sleeves as an example:

A protective shaft must be made before processing. The primary purpose of shaft protection is to cover the inner hole of the thin-walled sleeve with its original size, fix it in front and back to process the outer circle without deformation, and maintain the quality and accuracy of the outer circle processing. Therefore, the processing of the protective shaft is a key link in the process of processing thin-walled casing. Carbon structured round steel can be selected for processing the shaft guard blank;

To ensure that the workpiece can be processed in one go, a clamping position and cutting allowance should be reserved for the rough embryo.

Firstly, heat treat the raw material and adjust its hardness to a manageable scale.

Use an active centering three jaw chuck to firmly clamp the workpiece, cut the end face, and roughen the inner circle. Leave an allowance of 0.1-0.2mm for precision cutting, and machine the required cutting allowance to meet the requirements of excessive fit and roughness of the protective shaft. Remove the inner hole cutter, insert the protective shaft to the front, clamp it with the tail seat according to the length requirements, change the outer circle cutter to roughly mill the outer circle, and then finish milling to meet the drawing requirements.

The above method for processing thin-walled casing solves the problem of deformation or resulting in dimensional and shape errors that cannot meet the requirements. When reprocessing thin-walled parts, only by mastering the techniques and methods, CNC machining centers can process and produce thin-walled parts in bulk.