The provisions of various types of products are different for aluminum shells. The actual situation is mainly manifested in appearance and specifications. People who have touched aluminum shell processing know that there are two processing processes in the manufacturing industry, namely CNC processing, die casting processing , Aluminum shell processing and other processes. Let me have compiled the relevant content, let's take a look.

The difference between aluminum shell CNC processing and die casting processing:

Different processing methods:

The aluminum shell CNC processing refers to the use of a computer for precision CNC machining. Under the control of the computer, the aluminum shell is refined. Under this processing process, the aluminum shell can be achieved. Cut, non -penetrating pattern or texture carving, punching treatment at the bending of aluminum shell, and surface treatment of non -flat planes can be completed during CNC processing. Manufacturers with personalized and high requirements for aluminum shells are generally inevitable to apply to this category.

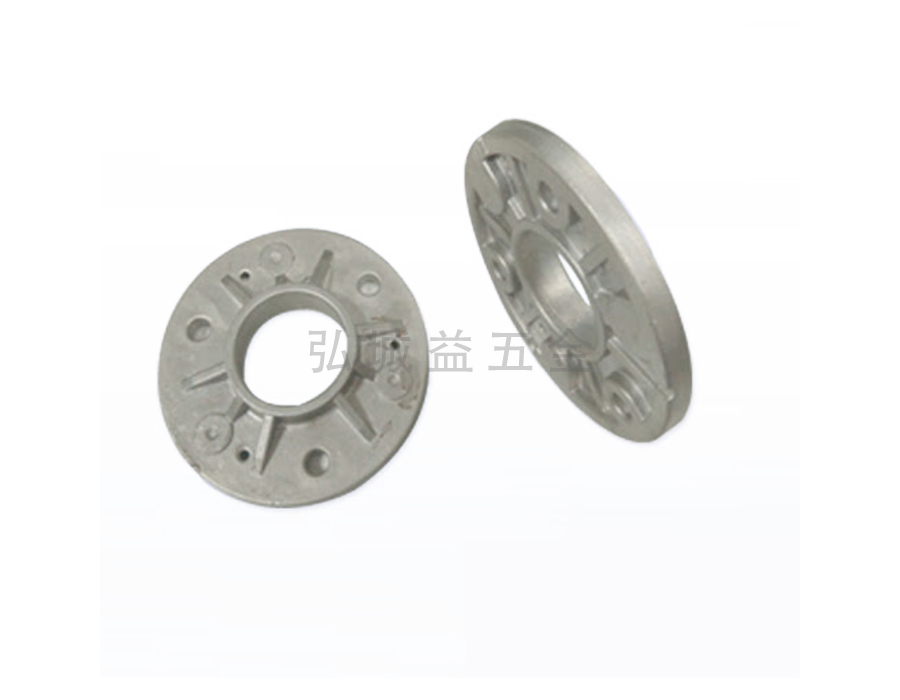

Dieted casting processing uses the mold cavity to apply high pressure to the melted metal to form the surface effect similar to molds. Some simple punching and molding work can be performed during the die casting process. Compared with CNC processing It is not possible to perform very complicated surface treatment.

The difference between aluminum shell CNC processing and die casting processing is the processing method. It can also be seen from the above content that in order to produce and process the qualified aluminum shell, you need to choose the corresponding processing process according to the need for production. In addition, we must also consider production costs. In the case where both processing processes are feasible, which one is more convenient and beneficial to choose, not to say which one looks better. Planting is more suitable for you, after all, this is very important.