If the production scale of Zhongshan CNC processing manufacturers can use a high -precision and high productivity rough manufacturing method. Although the one -time investment is high, the average cost distribution to each rough is less. Moreover, due to the high productivity of rough manufacturing methods with high accuracy, it not only saves raw materials, but also significantly reduces the amount of mechanical processing labor.

In addition, the high precision of the blank can simplify the craftsmanship and process equipment and reduce the total cost of the product. In order to improve the service life of CNC equipment, it is generally required to avoid direct thermal radiation such as sunlight, and to avoid excessive humid, dusty or corrosive gases. Precision CNC equipment should be far away from equipment with large vibrations, such as stamping and forging equipment.

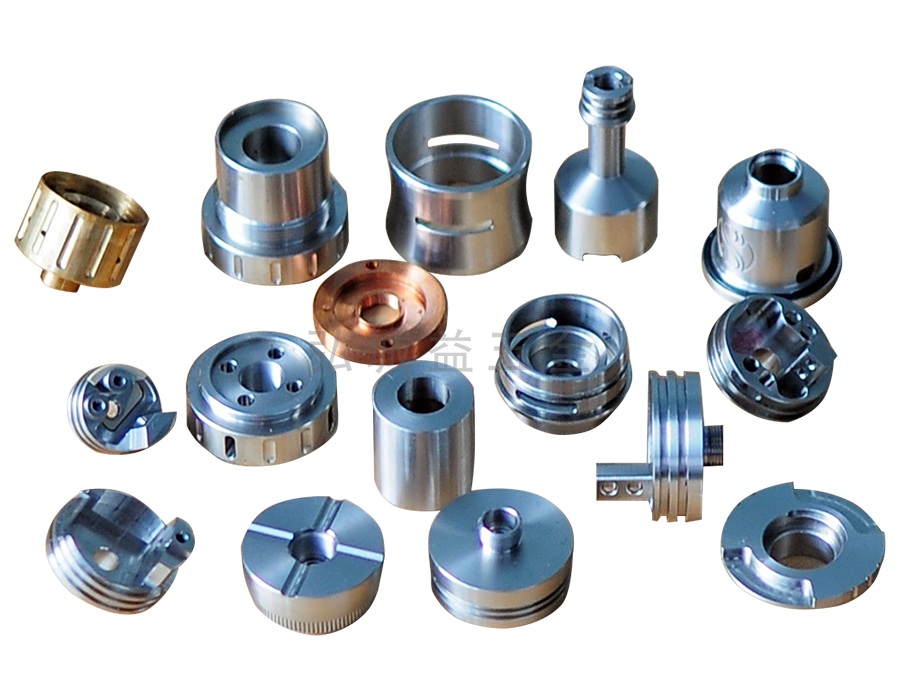

After CNC processing is almost popular, you will find that the advantages of CNC processing are worth your preference for CNC processing. Take a look! 1. The quality of processing is stable, the processing accuracy is high, and the accuracy of the repeated accuracy is high, which can meet the processing requirements of the aircraft;

3. Under the circumstances of multiple varieties of small batches, production efficiency is high, which can reduce the time of production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the use of good cutting; Parts do not require complicated workflow. If you want to change the shape and size of the parts, you only need to modify the processing program of the parts, which is suitable for the development and modification of new products.