In the hardware CNC processing plant, the processing CNC processing parts must be lubricated, which is indispensable in the whole process of deepening. The application of lubricating oil in the process of die casting is to better reduce friction, improve the duration of the use of the mold, reduce the thinness of the risk position, and improve the surface quality of the hardware CNC. Therefore, during the entire process of hardware CNC processing, how do we sometimes use the isolation layer to solve the CNC hair embryo?

This type of isolation layer is solved to thin and deep processing processes of CNC. In thin and depth, the lubricant is used to reduce friction and cooling mold shell. Do not apply dry friction. In the process of thinning, in addition to normal application lubrication, some materials must also be performed to solve the isolation layer.

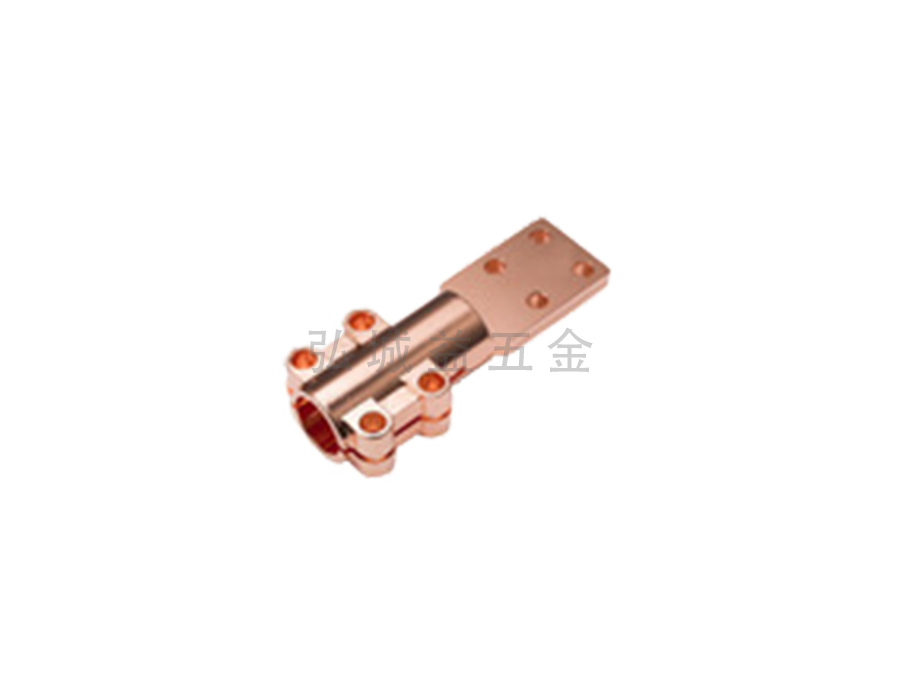

For example, when drawing cast iron parts, electroplating copper and acid phosphorusization are often carried out on the surface layer of the embryo. Lubricating characteristics; when pulling stainless steel plates, high -temperature carbon steel and other parts, the mold is compared with severe tight tightness and enhances the pressure resistance strength. Therefore, it is necessary to use the isolation layer to solve the embryo surface layer.

Among the technical professional CNC manufacturers, the process of the entire process of CNC processing is clearer, and it clearer the parts that need to be used in the idealization of customers. Therefore, the selected manufacturer is an important stage. Customers reduce costs and high -quality goods from the source.