With the progress of society, the use of processing centers is becoming increasingly widespread. The mixed variety of processing centers in the current market makes some new companies unsure how to choose processing centers and what types of processing centers to do.

1. Parts produced in small batches and multiple times

2. Parts with disordered shapes and high machining accuracy that cannot be processed by universal CNC machines or are difficult to ensure machining quality

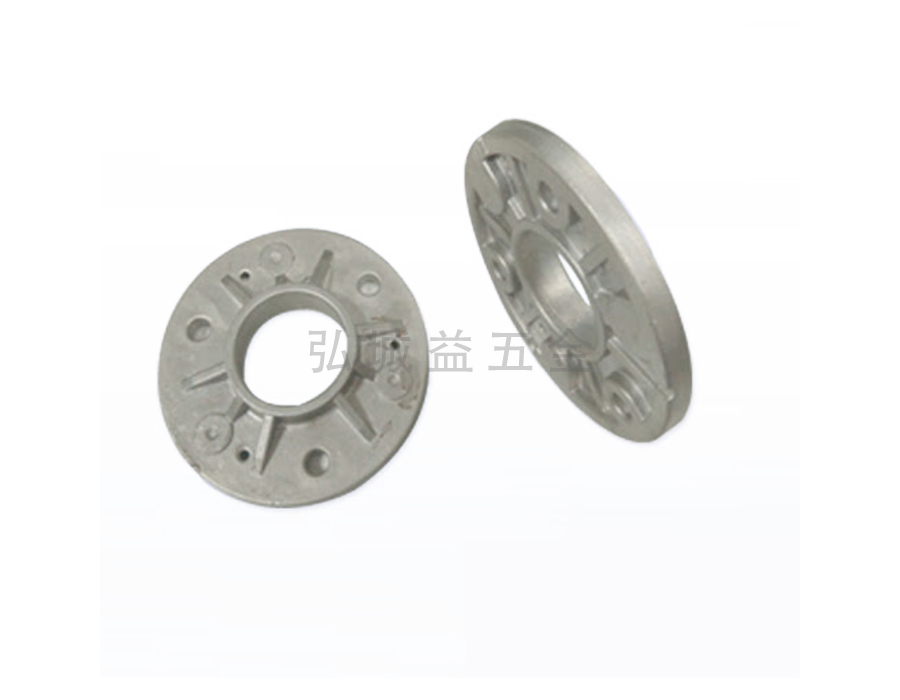

3. During the machining process, it is necessary to carry out multiple processes, such as milling, boring, spot facing, or tapping, in one clamping process

4. Parts that require strict tolerance control

5. Workpieces with large cutting allowance

6. Shell or box shaped parts with difficult to measure, difficult to control feed, and difficult to control cavity standards

7. Technology, describing parts that may change