1. What are the advantages of high -speed drilling machine

In the field of metal cutting, the basic functional processing of drilling, milling, and attack is no problem in vertical CNC machine tools, but as the requirements of manufacturing processing are getting higher and higher To meet customers' higher needs, faster and higher -precision machinery and equipment are already popular needs, and drilling centers (also known as high -speed drilling centers) can meet such requirements.

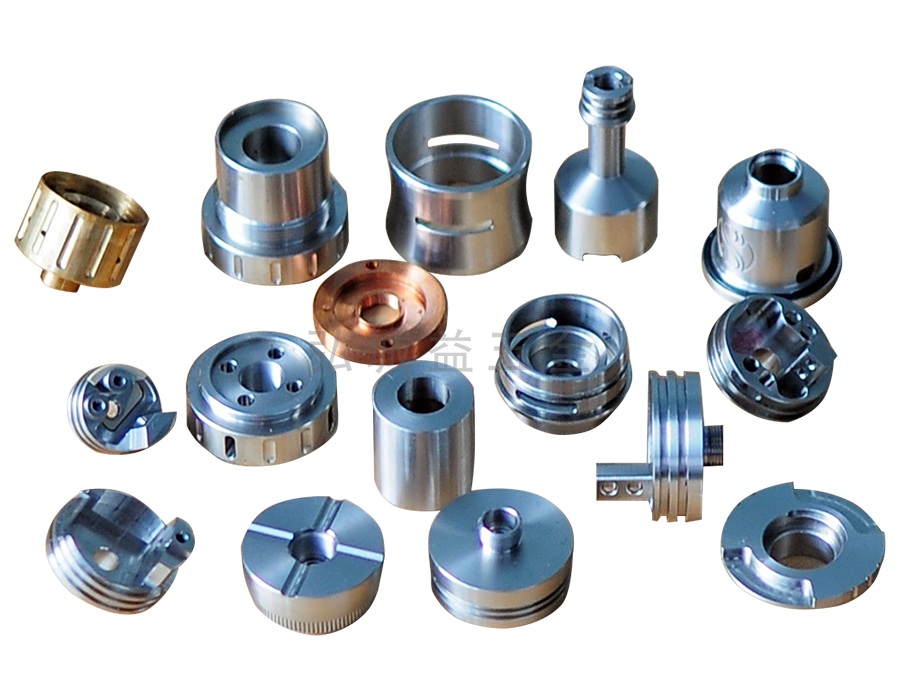

The X -axis itinerary of the drilling center does not exceed 700mm, and the Y axis does not exceed 400mm. It can be said that the drilling center is born for small parts such as the 3C industry, the electronics industry, and the medical device. The drilling center is used for processing of small parts or products, and its efficiency is extremely high, so it has become more and more popular in recent years. High -speed Comprehensive Processing Center

2. What are the differences between drilling center and high -speed processing center

From a structure perspective, the drilling center and high -speed machining center are very similar in terms of spindle speed. But in fact, there is a small difference between drilling centers and high -speed processing centers. The drilling center can be called a drilling center. Of course, it is because of its drilling to attack the tooth. The drilling center is also more "flexible" than the high -speed processing center. The so -called flexible refers to the fast feed center of the drilling center faster than the high -speed processing center. The drilling center is more special, that is, its flying saucer -type knife library, the flying saucer -style knife database has a very fast time. Generally, the knife can be completed within 1.2 seconds. The speed is much faster than the high -speed processing center. However, the drilling center is not a panacea. Its itinerary is not as large as a high -speed processing center, and the cutting intensity is not as good as the high -speed processing center. In terms of diversity, the drilling center is not as good as a high -speed processing center. Drilling Dental Machining Center

Method to improve the speed of high -speed processing center

The fundamental starting point of the automatic knife exchange at a high -speed processing center is that in the processing process of multiple tools, the auxiliary processing time is reduced by automatic knife. In the high -speed processing center, due to the significant improvement of the cutting speed, the equipment of the automatic sword replacement equipment and the blade library should be considered as shorter as possible, so as to cooperate with high -speed cutting machine tools. So what are the ways to change the knife speed of the high -speed processing center? There are mainly the following aspects:

Improve the speed of movement on the basis of the traditional automatic knife equipment, or choose a faster mechanism and drive element. For example, the speed of the knife of the mechanical cam structure is much higher than the hydraulic and pneumatic structure.