Many friends often ask me what is the difference between carving and milling machines and CNC machining centers. It seems that both types of machine tools are similar, but their functions are actually different. Today, let's learn about the difference between carving and milling machines and machining centers.

When machining small molds with small cutting tools, machining centers may appear inadequate and costly. The advantage of carving machine is carving. If the processing Hardness is relatively large, it will also appear powerless. The emergence of carving and milling machines can be said to fill the gap between the two.

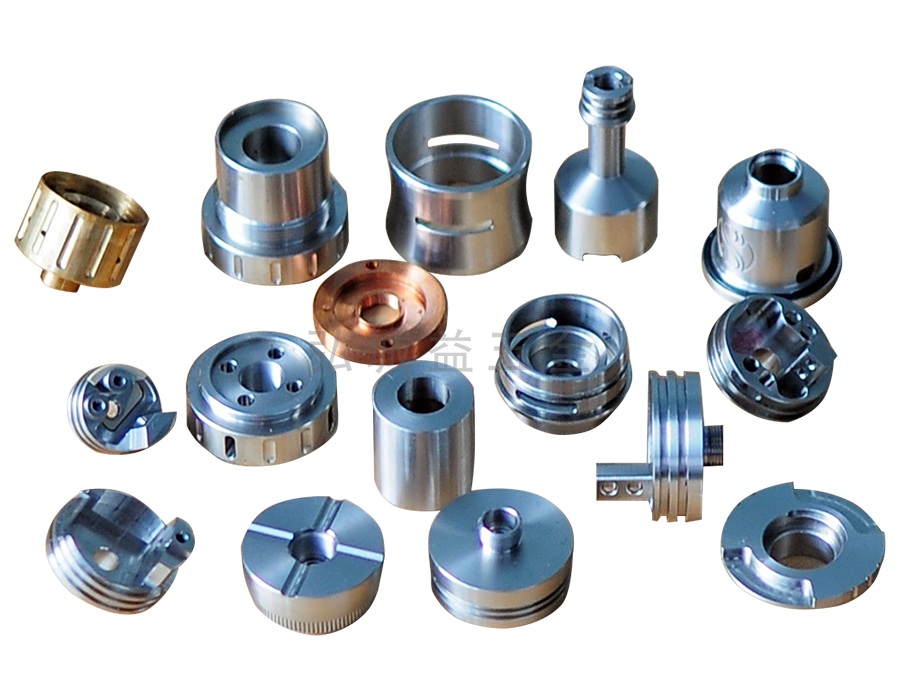

The machining center can achieve centralized processing of multiple processes such as milling, drilling, boring, reaming, and tapping after one clamping of the workpiece. The function emphasizes "milling", and the machining center requires a general speed for the CNC system. The spindle speed is around 0-8000RPM, which is particularly suitable for heavy cutting. The rough machining center generally adopts a cantilever type and has a relatively large volume.

Engraving and milling machines generally use a gantry structure, which can be divided into pillar type and fixed beam type. Currently, the majority of engraving and milling machines are fixed beam type. It can be carved or milled. On the basis of the carving machine, the power of the spindle and servo motor is increased, and the bed bears the force while maintaining the high-speed of the spindle. More importantly, the accuracy is very high. Engraving and milling machines are also developing towards high speed, commonly known as high-speed machines, which have stronger cutting ability and very high machining accuracy. They can also directly process materials with hardness above HRC60, forming in one go and suitable for precision machining. The engraving and milling machine requires a high-speed CNC system with a spindle speed of around 3000~30000RPM.

CNC milling and machining centers are processing equipment used to complete workpieces with large milling quantities. CNC engraving and milling machines are used to complete small milling quantities or soft metal processing equipment. High speed cutting machine tools are processing equipment used to complete moderate milling quantities and minimize the grinding amount after milling.